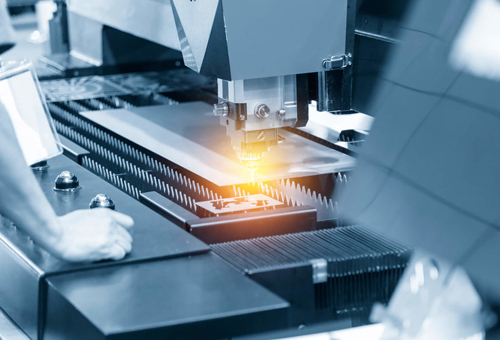

Copper is a popular alloy in various manufacturing industries because of its appearance and many important properties. It is soft, malleable, and easy to work on. Copper is highly reflective and conducts heat excellently. With this metal, you can produce clean cuts and get accurate and precise components. However, choosing the right gas is important as it directly affects the efficiency of the process.

‘Can you laser cut copper with nitrogen?’ It is not strange when this question comes to mind as a novice or expert in copper laser cutting. This article will explain how and when to use nitrogen as the assist gas when cutting copper workpieces. It will explore the benefits of nitrogen gas, cutting parameters to consider, and other gasses you can use for laser-cutting copper.

Can You Laser Cut Copper with Nitrogen

Yes, it is possible to laser cut copper workpieces using nitrogen as an assist gas. Nitrogen is one of the most recommended gasses because of the challenges one might face when cutting copper with a laser beam. Copper is a highly reflective metal which reduces the amount of energy absorbed during the process. Additionally, this metal also tends to create plasma which can deflect the laser beam.

The use of nitrogen when laser cutting copper makes the process more efficient because of many reasons. Nitrogen has a high cooling capacity and prevents the creation of plasma caused as a result of high temperature. Furthermore, this gas is inert and does not react with the workpiece in any way. Furthermore, you can be sure not to react when in contact with the surrounding air. Hence, the cutting process will not produce harmful oxides and fumes.

Nitrogen has a low thermal conductivity and results in a smaller heat-affected zone. When using nitrogen gas, the surrounding materials are not affected and retain their original properties. Additionally, this gas is non-toxic, nonflammable, and environmentally friendly. It is also affordable and easily accessible.

Benefits of Assist Gasses in Copper Laser Cutting

Assist gasses play a huge role when cutting copper metal using a laser. They are directed through a nozzle and interact with the cut zone. Assist gasses are indispensable in the laser cutting operation and provide the following benefits.

Heat Dissipation

Using assist gasses when laser cutting copper helps to dissipate heat from the cutting area. They reduce the risk of burning and provide a smoother cutting action. Furthermore, most assist gasses have a cooling effect and adequately disperse heat through different means. All these help to preserve the workpiece properties and prevent thermal damage.

Enhanced Cut Quality

Assist gasses increase the accuracy and quality of the cuts using lasers in many ways. These gasses serve as a protective shield and reduce unwanted reactions. The reactions when not controlled forms unwanted substances and oxides that can affect the cut edge quality. Furthermore, assist gasses blow away the melted material from the cut zone. This action reduces roughness, burrs, and other imperfections.

Prevents Copper Vapourization

Copper when heated to a very high temperature heats up and evaporates to produce toxic fumes. The use of assist gasses displaces oxygen and prevents this reaction. Furthermore, these gasses reduce the incidence of rapid cooling and heating. This is because you are able to minimize the energy input and prevent overheating.

Improved Cutting Speed

Assist gasses increase the speed and efficiency of the laser cutting operation. A good and proper flow of the gas improves laser beam quality and helps to maintain focus. Additionally, using assist gasses minimizes deflection and produces a straighter and more focused beam of light. All these features provide a faster cutting action and improve productivity.

Enhanced Safety

Assist gasses enhance safety and protect both the operator and the surrounding environment. These gasses reduce the production of harmful fumes and that can cause respiratory illnesses. Additionally, they reduce spattering and hot splashes when laser cutting copper metal. Furthermore, assist gasses help to minimize air pollution as a result of fume and particle emissions. They provide a more controlled process and minimize contamination of the work area.

Laser Cutting Parameters for Copper with Nitrogen

When laser cutting copper, you have to properly optimize certain parameters to get the best result. Below are some parameters you must set correctly and best practices to keep in mind.

Laser Type

There are different types of lasers one can use when cutting. However, the most ideal for copper is fiber lasers. Fiber laser has a high power density that allows you to process copper alloys fast to create high-quality parts. Copper has a high absorptivity at the wavelength emitted by this laser type. This enables a faster cutting speed and smoother finish.

Laser Power

You should also modify the laser power of the cutter. If possible, use the highest power that can overcome the thermal conductivity of copper. Note that you should not increase the power to more than the required one as it can cause damage to the workpiece. The laser power should be between 1000-6000W based on the workpiece thickness. For example, go for 1000W when the thickness is 1.5mm. However, 3000W is perfect for a workpiece that is about 6mm thick.

Cutting Speed

The cutting speed you use when handling copper workpieces will determine the cut quality. The laser power, cutting angle, and focal point position will affect the speed. Consider starting at a low speed of 0.5-1.0 m/min and then increasing gradually. Furthermore, you should modify the cutting speed keeping in mind the workpiece thickness. Cut thin copper sheets at a fast speed and use slower speed for thicker ones. This will help prevent overheating and increase productivity.

Gas Flow Rate

You should also optimize the volume of nitrogen gas that flows out of the nozzle. Choose the appropriate flow rate after considering the cutting speed, laser power, metal thickness, and nozzle distance from the workpiece. Using too low a flow rate will lead to inadequate gas coverage and insufficient material removal. However, you will experience rougher cut edges and a wider kerf width when the flow rate is higher than required.

Other Gasses for Laser Cutting Metal

In addition to nitrogen, there are other gasses you can use when laser cutting copper metal. Each gas has its unique advantages and is suitable for various purposes. Let’s explore some of them

Argon

Argon is another gas suitable for laser cutting copper. This gas is inert and protects the cut zone from any reaction. It maintains a clean cutting edge and provides a high-quality finish. When working with thin copper sheets, go for argon as the assist gas. However, you may have to reduce the cutting speed when using argon to get the best results. Additionally, argon is relatively expensive and increases production costs.

Helium

The use of helium as the assist gas in copper laser cutting is nothing new. Helium has a high thermal conductivity and dissipates heat quickly when cutting. As a result, there is less heat damage and thermal distortion. Furthermore, this gas achieves a higher cutting speed and reduces the likelihood of plasma formation. This feature helps to improve cut quality and streamline the entire cutting operation.

Conclusion

It is possible to laser cut copper using nitrogen as the assist gas. However, the result depends on material thickness, laser power, and gas flow rate. Nitrogen gas achieves a clean cut and boosts productivity. For thicker, thinner, or more challenging cuts, other gasses including helium and argon may be needed. Do you have further questions and clarifications? Reach out to a reputable CNC laser cutting service provider and leverage their experience and expertise.

Keep an eye for more news & updates on VentsBreaking!